Blue Shuttle +That never launched

Photographs from 1985(see Gallery)show the only time a space shuttle vehicle ever stood at Vandenberg Air Force Base’s Space Launch Complex 6 (SLC6). The concept was nicknamed “The Blue Shuttle” by the Air Force associated with the project because it was an easy way to define the difference between “NASA Space Shuttle” and the Shuttle vehicles that the Air Force would fly on a North/South orbit. This orbit would permit flights over countries in the northern latitudes of Europe.

The plan to erect the shuttle was called the Vandenberg Launch and Landing Site Utilization Plan and was written by William Gleason (Me). The Orbiter OV 101 was flown in piggy-back on the 747 designed for that function and landed at the VAFB runway that had been extended to two miles. It was then demated from the 747 at the Mate/Demate facility and towed inside Orbiter Maintenance Facility to check out the facility interfaces. Of note: OV101 was originally built for initial flight tests at Edwards AFB CA and never flew in space.

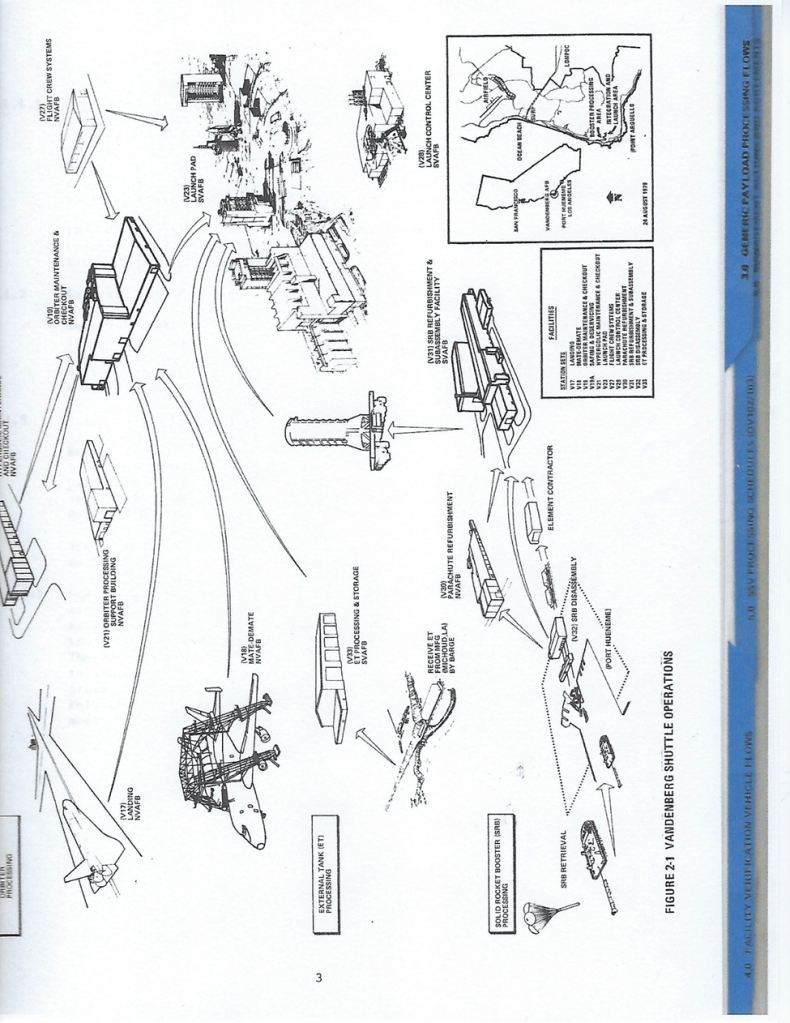

The Shuttle Vehicle erected at Vandenberg AFB CA, consisted of the Shuttle Orbiter, two Solid Rocket Motors, and an External Tank. All made the uncharted and sometimes perilous journey to South VAFB to verify the delivery routes required for their delivery. (Refer to Figure 201 for a diagram of vehicle component flow.)

V19 Orbiter Maintenance Facility The Orbiter was positioned verrtically in the OMCF. Facility and support equipment were verified. The Orbiter was jacked, leveled and landing gear retracted. A simulated payload installation/removal was performed to assure payload processing areas support equipment and procedures worked. They did.

V33 External Tank and Checkout Facility

The External Tank was loaded on the barge in Michoud, LA used to deliver ET’s to Kennedy Space Center (KSC). To support the Vandenberg Facility Verification Vehicle Testing it was transported to the ET Processing and Storage Facility (V33) through the Panama Canal and up the California Coast to the dock at South Vandenberg and then to the V33 ET Processing Facility.

V31 SRB Refurb. And Subassembly Facility (SRSF)The SRB engine segments for the two motors were transported by train cars to V32 the SRB Refurb and Subassembly Facility. The original plan called for live SRB’s to be used for FVV processing validation. It was decided later to use “inert” SRBs,, i.e. the metal segments were filled with cement at the factory instead of propellants simulating their weight without requiring “live” safety clearances when handling the segments for stacking.

Blue Shuttle

Kennedy Space Center (KSC) Over Flight

Photographs from 1985(see Gallery) provide a look at the only time a space shuttle vehicle ever stood at Vandenberg Air Force Base’s Space Launch Complex 6 (SLC6). The concept was nicknamed “The Blue Shuttle” by the Air Force personnel associated with the project because it was an easy way to define the difference between “NASA Space Shuttle” and the Shuttle vehicles that the Air Force would fly on a North/South orbit. Attaining this orbit would permit flights over countries in the northern latitudes of Europe.

The Shuttle Vehicle erected at Vandenberg AFB CA, consisted of the Shuttle Orbiter. 2 Solid Rocket Motors, and an External Tank. All made the uncharted and sometimes perilous journey to VAFB to validate the delivery routes required for their delivery. (Refer to Figure 201 for a diagram of vehicle component flow.) The plan to erect the shuttle was called the Vandenberg Launch and Landing Site Utilization Plan.

The Orbiter OV 101 was flown in piggy back on the 747 designed for that function and landed at the VAFB runway that had been extended to two miles to permit delivery of the Shuttle. The aircraft was taxied to V18 Mate/Demate facility where the shuttle was de-mated from the 747 The Orbiter was then towed to the Orbiter Maintenance facility to checkout the facility interfaces. Of note: OV101 was originally built for initial flight tests at Edwards AFB CA and never flew in space.

V19 Orbiter Maintenance Facility

The Orbiter was positioned in the OMCF. Facility and support equipment were verified. The Orbiter was jacked, leveled and landing gear retracted. A simulated payload installation/removal was performed to assure payload processing areas support equipment and procedures were validated.

V33 External Tank and Checkout Facility

The External Tank was loaded on the barge in Michoud, LA used to deliver ET’s to Kennedy Space Center (KSC). To support the Vandenberg Facility Verification Vehicle Testing it was transported to the ET Processing and Storage Facility (V33) through the Panama Canal and up the California Coast to the dock at South Vandenberg and then to the V33 ET Processing Facility.

V31 SRB Refurb. And Subassembly Facility (SRSF)

The SRB engine segments for the two motors were transported by train cars to V32 the SRB

Refurb and Subassembly Facility. The original plan called for live SRB’s to be used for FVV processing validation. It was decided later to use “inert” SRBs,, i.e. the metal segments were filled with cement at the factory instead of propellants simulating their weight without requiring “live” safety clearances when handling the segments for stacking.

Launch Pad Operations

FVV/STV Operations at the pad consisted of SRB stacking, ET erection , and orbiter mating and STV installations, platform/facility clearances and interfaces will be validated during SSB element stacking operations.

SRB stacking will start with the positioning of the SRM transporter and half skirt in the Mobile Service Tower Bridge crane envelope. SRB Aft Skirts for each SRB (2) and segments will be hoisted and set down until both SRB stack are completely stacked.

The ET will then be positioned in front of the Payload Change Room (PCR), attached to the strong back and lifted and rotated to the vertical position the PCR will be brought forward and the ET attached to the SRB’s. Clearances and interface were be validated.

The Orbiter was positioned, attached to the PC strong back, and lifted and rotated to the vertical position. The PCR was brought forward. The orbiter wasl mated to the ET. The strong back was removed from the orbiter and the PCR moved back to the payload processing room to pick up the Payload Test Vehicle

The Payload Test Vehicle was used as the Payload Verification Vehicle (PVV) during the launch pad verification of the payload preparation room utility were moved in and out of the PPR test cells. Clearances and interfaces were vaidated.

After payload operations the stacked Shutte Vehicle was de-stacked.

SSV elements were returned to their respective processing facilities. OV101 was retuned to the Mate/Demate Fixture and mounted on the 747 carrier. It wasreturned[BG1] to the desired NASA facility.

A flight shuttle was never launched from California. Even while the configuration of the vehicle and its intended north-south orbit were an issue. Without getting to technical about it, flying any space craft in a north-south orbit requires more energy than flying east west. It has to do with centrifugal force basically and the rotation of the earth. The bottom line was that to launch from VAFB, CA would require more energy to lift the projected payloads into orbit i.e. more thrust from the Solid Rocket Motors One solution was to change the metal casings for the segments to wire wound fiber cases. Then came the Challenger accident.